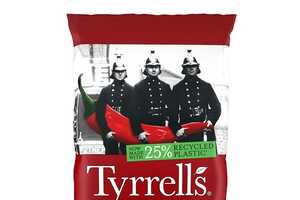

Cooking Oil-Based Snack Packaging

Viva Energy has Created Packaging Solutions from Upcycled Oil

Colin Smith — March 3, 2025Viva Energy has pioneered an innovative approach to sustainable packaging by utilizing used cooking oil (UCO) as a feedstock for producing bio-based polymers. This development took place at the company's Geelong Refinery in Victoria, Australia, where a batch of UCO was processed through its catalytic cracker and polypropylene plant. The resulting material, certified under the ISCC+ standard, is suitable for creating food-grade recycled plastic packaging. The UCO was sourced from Intersnack ANZ, a snack manufacturer known for brands like Kettle Chips and Cheezels. This initiative aligns with Viva Energy's broader efforts to address plastic waste challenges and complements its ongoing plastic recycling project with Cleanaway, which handled the collection and purification of the UCO.

The project represents a significant step toward establishing a circular economy in the packaging industry. Viva Energy has invested in infrastructure upgrades at the Geelong Refinery to facilitate the use of alternative feedstocks like UCO. The company aims to scale up this process, potentially transforming the refinery into a broader energy hub. Intersnack ANZ plans to use the bio-based material for its snack packaging, contributing to its goal of reducing scope 3 carbon emissions. This collaboration highlights the growing demand for sustainable packaging solutions and underscores the importance of regulatory support to ensure the success of such initiatives.