Textiles-to-Textiles Recycling

Jack Wolfskin Revolutionizes Apparel with Textiles Recycling

Grace Mahas — February 28, 2024Jack Wolfskin is setting a new standard in sustainable fashion with its groundbreaking 'Textiles to Textiles' recycling process, an initiative that turns textile waste into high-performance, weatherproof apparel. This innovative approach addresses the critical issue of textile waste, with an alarming 85% of discarded textiles in the U.S. ending up in landfills or incinerated, contributing to environmental pollution.

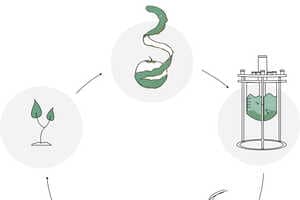

The process begins by collecting used polyester textiles and manufacturing scraps, which are then stripped of non-textile elements and chemically processed into PET granules. These granules are spun into new polyester, dyed, and woven into fabric that meets the Global Recycling Standards. This cycle of repurposing ensures that each new product, such as the award-winning Highest Peak 3L jacket, offers the same high-quality weather protection (20,000mm waterproof head / 15,000g/m2/24hrs breathability) as virgin polyester-based products, without the environmental footprint.

By eliminating the use of single-use plastics and ensuring all products are 100% PFAS-free and bluesign® approved, Jack Wolfskin not only minimizes waste but also prevents the release of harmful microplastics. The "Textiles to Textiles" technology signifies a significant move towards a circular economy in the apparel industry, promising a sustainable future with zero waste and maximum performance